Download GibbsCAM for Windows PC for free. CAM software of the highest caliber is intended to simplify the programming process for CNC machine tools. It provides the necessary flexibility and capacity to efficiently manufacture components. Its intuitive interface guarantees manufacturing engineers, CNC programmers, and machinists maximum efficiency.

A Synopsis of GibbsCAM

It is notable for being an all-encompassing CAM solution that accommodates the requirements of numerous CNC machines. The software’s user interface is designed with NC programming in mind, ensuring that it is straightforward to navigate and can be personalized to suit individual needs. A comprehensive collection of error-free post processors that are developed internally guarantees precise programming for a wide range of CNC machines. With its industry-leading machine simulation capabilities, users are able to precisely visualize and validate machining processes, even when dealing with intricate machines.

Individual CAM Software Package

For programming any CNC machine, it provides a unified platform that obviates the necessity for employing numerous software solutions. This feature optimizes the process, diminishes intricacy, and improves productivity, enabling users to effortlessly oversee every machining operation through a single interface.

User-Considerable Interface

Its interface is designed to be customizable with the end-user in mind. It incorporates well-known terminology, user-friendly iconography, and rational procedures. Notwithstanding one’s level of expertise in CNC programming, the process of navigating it is uncomplicated, guaranteeing a seamless and fruitful undertaking.

Post-processors devoid of every error

An outstanding characteristic is the comprehensive collection of validated post-processors that have been internally developed by seasoned engineers. The post-processors have been carefully engineered to produce G-codes that are precise and devoid of errors, all while ensuring that particular CNC machines operate with maximum efficiency and dependability.

Accurate Simulation of Machines

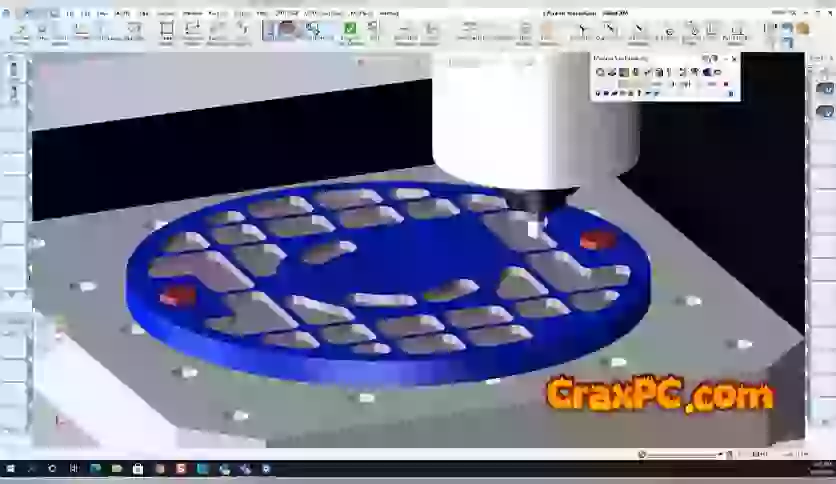

The sophisticated machine simulation functionalities of the software offer an authentic virtual setting to examine and authenticate machining procedures. Precise simulations of material removal, toolpaths, and collisions enable users to reduce error risk and maximize output.

Programming Multi-Task Machining (MTM)

Users can program multitask machining operations, such as turning, milling, and drilling, with greater efficiency using this application. By utilizing this all-encompassing functionality, users are able to optimize the potential of their CNC machines, leading to increased production output and superior quality of components.

Conditions of the System

System Operation: Windows 11/10/8.1/8/7

Processor speed of at least 1 GHz (2.4 GHz is suggested)

RAM: 2 GB (at least 4 GB is advised).

Free space on the hard drive: 4 GB or more is advised.

To conclude,

GibbsCAM provides a robust yet intuitive solution for CNC programming, incorporating functionalities specifically designed to optimize output and streamline operations. Its multitask machining capabilities, error-free post processors, intuitive interface, and precise machine simulation establish it as the software of choice among manufacturing engineers, CNC programmers, and machinists. By selecting it, users have the ability to optimize the performance of their CNC machines, reduce errors, and expedite their machining processes.